Ethylene Oxide (EO) is a low temperature gas that can penetrate thin films and breathable materials in order to sterilize effectively.

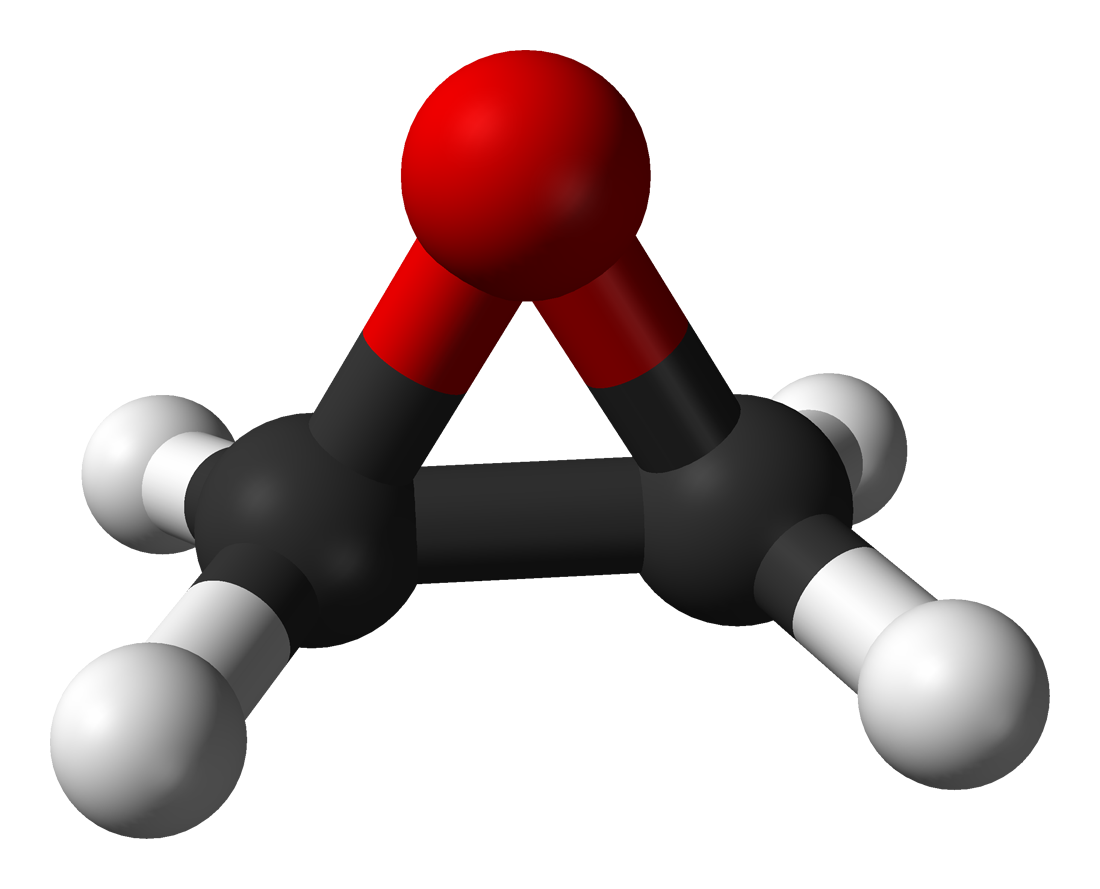

EO is an alkylating agent and alters the amino acids that make up a microorganism's proteins, DNA and RNA.

EO is most useful when a product cannot be exposed to heat, humidity, or radiation and thus is useful for a wide variety of medical devices that aren't enabled through other processes. For most types of thin films and breathable packaging EO will penetrate through and sterilize effectively.